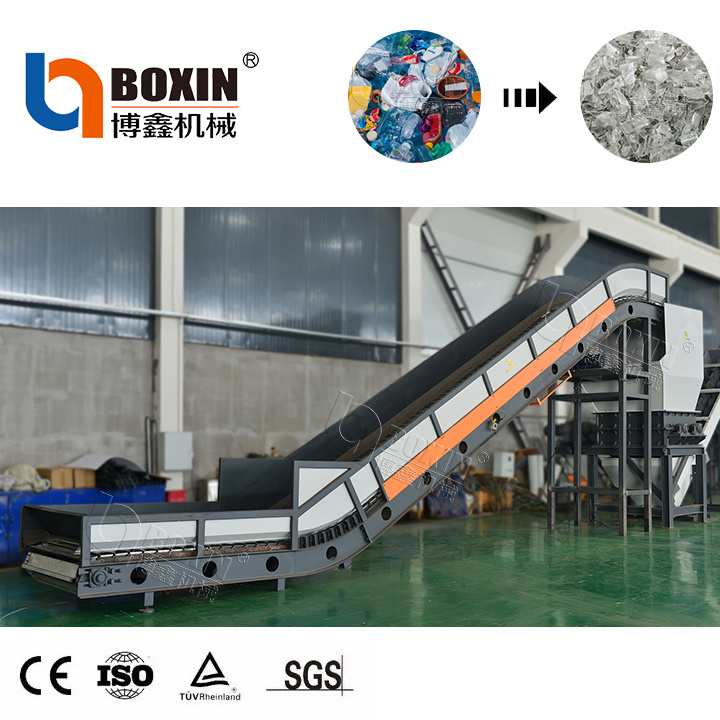

Waste Pet/HDPE/LDPE/PP/PE Bottles Films Woven Bags Plastic Recycling Pelletizing/Granulator/Granulation/Flakes Scrap Crushing Washing/Squeezing Shredder Machine

Description:Waste Pet/HDPE/LDPE/PP/PE Bottles Films Woven Bags Plastic Recycling Pelletizing/Granulator/Granulation/Flakes Scrap Crushing Washing/Squeezing Shredder Machine - China Waste Plastic Recycling Machine and Plastic Recycling Machine

3000kg / H Waste Pet/HDPE/LDPE/LLDPE Bottles Films Plastic Recycling Line/Flakes Scrap Washing Machine

WHAT WE CAN OFFER YOU

PP PE BOTTLE RECYCLING MACHINE

PET BOTTLE WASHING waste pet bottle recycling machine AND PELLETIZING MACHINE

PET bottle washing line :

XINTING Good Supplier plastic bottle wash recycle line PET bottle washing recycling machine

1-Plastic recycling washing machine is applied in PET waste bottle or sheet recycling field.

2-Through crushing, washing and dry process, the waste bottle or sheet will become to be bottle flakes. The flakes are widely used in plastic industry, like sheet, and profile production.

3-The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent film and sheets, etc. The top class flakes can be used to blow bottles again.

4-Recycling machine can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products are very clean.

5-Recycling plastic machine output we can supply is from 300kg/h to 3000kg/h.

For the total plastic bottle washing machine

Product Description of plastic recycling machine:The pet bottle recycling machine is specially designed to produce fiber use PET flakes.

The flakes can be used for the 2-D, 3-D PSF, filament yarn, PET strap, PET sheet or PET film.

The pet bottle recycling line can adopt the PLC automatic control of the full line to control the final products quality and save energy.

Pet bottle recycling line can be equipped with the Europe automatic material sorting system and color sorting system.

plastic recycling machine can be customized according to the raw material and customer requirement

No. | Machine List | Function |

|---|---|---|

| 1 | Belt Conveyor | Bottles conveying |

| 2 | Bottle Label Remover | Remove above 90% labels for both common and compressed bottle; No flakes waste and no water consumption |

| 3 | Manual Sorting Belt | Manually sort out PVC bottle, labels, and other impurities |

| 4 | Belt Conveyor | Bottle conveyor tp crusher |

| 5 | PSJ1200 Crusher | Bottle crushing into flakes |

| 6 | Horizontal Screw Loader | Conveying flakes to next screw loader |

| 7 | Screw Loader | PET flakes conveying |

| 8 | Floating Washer | Wash flakes and remove floating materials as PP, PE and Caustic soda |

| 9 | Low Speed Friction Washer | Remove sand, mud and dirty |

| 10 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 11 | Screw Loader | PET flakes conveying |

| 12 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 13 | Screw Loader | PET flakes conveying |

| 14 | High Speed Friction Washer | Remove the glue and dirty |

| 15 | Screw Loader | PET flakes conveying |

| 16&17 | Floating Washer | Wash flakes and remove floating material as PP, PE and Caustic Soda |

| 18 | Spray Washer | Remove the Caustic Soda |

| 19 | Centrifugal Dryer | Drying and flakes moisture reach 2% |

| 20 | Pipeline Dryer | Hot air drying, moisture <1% |

| 21 | Label Flake Separator | Remove little amount of label and dust in PET flakes |

| 22 | Packaging System | Storage silo for PET flakes |

| 23 | Electric Cabinet | Electric control for the complete line, can be customized |

PET Flake Quality Reference Table:

| Moisture Content | <0.9% | Label | <20ppm |

|---|---|---|---|

| PVC | <20ppm | Variegated Tablets | <30ppm |

| Glue | <10ppm | pH | Neutral |

| PP/PE | <20ppm | Total Impurity | <100ppm |

| Metal | <20ppm | Flake Size | 12mm, 14mm or customized |

Production Consumption:

| Items | Average Consumption Per Ton Flakes |

|---|---|

| Electricity (kw/h) | 200 kw/h |

| Steam (kg) | 500 kg |

| Washing Detergent (kg) | 8 kg |

| Water (t) | 2m³ |

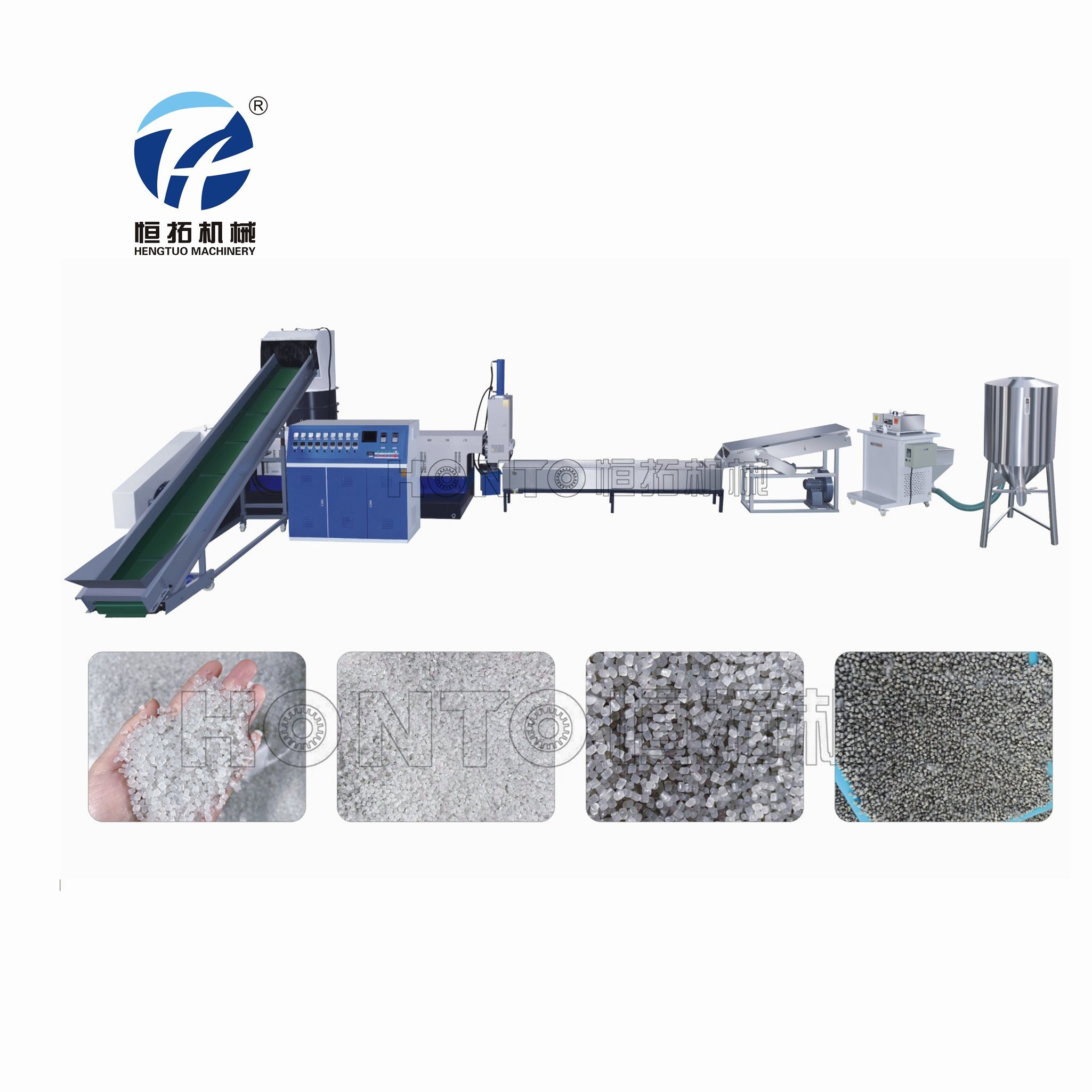

Plastic PET pelletizing machine

>>>Parameter table

Mode | Diameter(mm) | L/D | Rotating speed | Power(kw) | Capacity(kg/h) |

(r/min) | |||||

TSE-20 | 22 | 32-44 | 600 | 5.5 | 0.5-10 |

TSE-30A | 500 | 11 | 5-30 | ||

TSE-30B | 31 | 32-48 | 600 | 15 | 5-40 |

TSE-35A/B | 35.6 | 32-52 | 600-800 | 15-22 | 30-70 |

TSH-35B | 35.6 | 32-52 | 600-800 | 15-22 | 30-70 |

TSE-40A | 41 | 32-64 | 400 | 22 | 100-120 |

TSE-40B | 41 | 32-52 | 600 | 30 | 100-160 |

TSH-40B | 41 | 32-52 | 600 | 45-55 | 150-220 |

TSE-50A/B | 50.5 | 32-52 | 500 | 45-55 | 180-270 |

TSH-52B | 51.5 | 32-60 | 600 | 90-132 | 682 |

TSE-65B | 62.4 | 32-64 | 600 | 90 | 250-350 |

TSE-65C | 62.4 | 32-64 | 600 | 110 | 300-400 |

TSH-65B | 62.4 | 32-64 | 600-800 | 110-160 | 350-500 |

TSE-75B | 71 | 32-64 | 600 | 132 | 350-550 |

TSE-75C | 71 | 32-64 | 600 | 160 | 400-600 |

TSH-75B | 71 | 32-64 | 600-800 | 200-250 | 600-800 |

TSE-95A | 93 | 32-64 | 500 | 250 | 600-1000 |

TSE-95B | 93 | 32-64 | 600 | 315 | 800-1200 |

TSH-95B | 93 | 32-64 | 600-800 | 400-450 | 1200-1600 |

TSE-135A | 1333 | 32-64 | 500 | 550 | 1500-2250 |

pp Wovenbags pe film washing machine

PP PE FILM WASHING RECYCLING MACHINE

Application : Suit for recycling PP/PE waste film, Post consumer film, Food contaminated film, Garbage

film, Agricultural film, Mulching film, Greenhouse film, PP woven bags etc.

Specification : The production line is mainly composed of Plastic Film Shredder/ Plastic Film Granulator, Friction

Washer, Sink Floating Tank, Horizontal Centrifugal Dryer, Squeezer or Squeezer & Agglomerator. The whole

production line is easy to operate, efficient and low energy consumption.

Pelletziing machine video

Product Application

Waste PP PE Film Recycling Machine is mainly suitable for crushing and washing dirty plastic film into clean film flakes,like agriculture film,packing film,shopping bags,woven bags and so on soft plastic materials.

| Machine Model | Washing Capacity | Total Machine Electric Consumption | Total Machine Water Consumption (if you have dirty water treatment equipment,then water can be recycled) |

| HS-300 | 300KG/H | 80KWH | 1-2ton/hour |

| HS-500 | 500KG/H | 100KWH | 2-3ton/hour |

| HS-1000 | 1000KG/H | 160KWH | 3-4ton/hour |

Description for PP PE film washing line :

PP PE FILM WASHING LINE is designed to clean recycled plastic woven sack and plastic farm film, the machine is widely used for PET,PP,PE plastic cleaning and plastic bottle cleaning. Developing on the basis of advanced technology, the machine has advantages of stable performance, high output, energy efficiency, small floor area and good appearance. We can produce the machine according to client requirement.

There are 300-2000kg/h etc capacity , we need make quotations according to your detailed requirements .

PE FILM PELLETIZING MACHINE SPECIFICATION:

Main Technical Data:

Model/specification | Length-diameter ratio | Production(kg/h) | Screw speed(rpm) | Driving power (kw) | Center high(mm) |

SJ-30/25 | 25:1 | 1.5-10 | 15-150 | 5.5 | 1000 |

SJ-45/25 | 25:1 | 5-38 | 12-88 0-5 | 7.5 | 1000 |

SJ-65/25 | 25:1 | 20-85 | 13-130 | 22/7.3 | 1000 |

SJ-65-25A | 25:1 | 10-30 | 0-27 | 7.5 | 1000 |

SJ-65-25B | 25:1 | 10-45 | 0-37 | 11,15,18.5(customize as User) | 1000 |

SJ-90/25 | 25:1 | 50-100 | 33.3-100 | 5.5/18.3 | 1000 |

SJ-90A | 25:1 | 30-60 | 0-30 | 7.5 | 1000 |

SJ-90/25B | 25:1 | 60-90 | 0-30 | 22 | 1000 |

SJ-120/25 | 25:1 | 84-190 | 17-52 | 55/18.3 | 1000 |

SJ-150/25 | 25:1 | 50-300 | 7-42 | 100/75 | 1000 |

SJ-200/25 | 25:1 | 180-430 | 5-15 5-30 | 100/16.7 | 1000 |

Attached machinery | |||

Cooling water tank | Send grain windmill | Particle cutting machines | Tin the material storing barrels |

LX-2HP × 2sets | 0.8×1.0×2.3 | ||

2.2×0.6×0.8 | VS4p×2HP | ||

LX-3HP × 2sets | 0.8×1.0×2.3 | ||

2.2×0.6×0.8 | VS4p×3HP | ||

LX-5HP × 2sets | 0.8×1.0×2.3 | ||

2.5×0.8×0.9 | VS4p×5HP | ||

LX-5HP × 2sets | 0.8×1.0×2.3 | ||

3.0×0.8×0.9 | VS4p×7.5HP | ||

PLASTIC FILM SQUEEZING MACHINE

After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers' needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders.

Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps .The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~1000kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don't need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity.

Machine Pictures

Film Squeezing Machine Specifications | |

Motor Power | 180kw |

Rotating Speed | 10-90r/min |

Capacity | 1000kg/h~1500kg/h |

QUESTIONS AND ANSWERS:

Q:What about your machinery?

A:Seeing is believing.Our strength technical team guarantee the highest quality,not only of machine,but also of precisely control and final product.

Q:What about the price?

A:Our price is based on reasonable competition.

Q:What about after service?

A:We can offer 18months warrant since the machinery arrived at your factory except for durable parts.After warrant,we will offer space parts or repair service with or without charges.

In the midst of the market economy, Xinting Company has established a good reputation, pursued excellent products, and provided perfect services in a sincere attitude and full of passion. It has always been satisfied with your requirements and wishes, providing a comprehensive and in place service. . Xinting people will provide customers with high-quality complete sets of equipment and comprehensive technical support based on the development concept of "Great Industry for 100 years".

Zhangjiagang Xinting Machinery warmly welcomes users at home and abroad to come to the company to negotiate!

WELCOME TO VISIT ZHANGJIAGANG XINTING MACHINERY CO.,LTD.

本站曲谱部分来源于网络,仅供学习交流分享,吉他谱网不承担任何由于内容的使用所引起的争议及损失。如有侵权,可联系管理员删除处理。Article link:https://yunxiguoji.com/plastic-recycling-machine/856.html